Unlock Precision and Speed with Our Metal Laser Cutting & CNC Punching Combo Machine

The Amada EML-AJ at Fox delivers precision, durability, and efficiency by combining advanced laser and punching capabilities. Perfect for custom or large-scale projects, it ensures consistent results, fast lead times, and cost-effective solutions, overcoming concerns about quality, speed, and reliability.

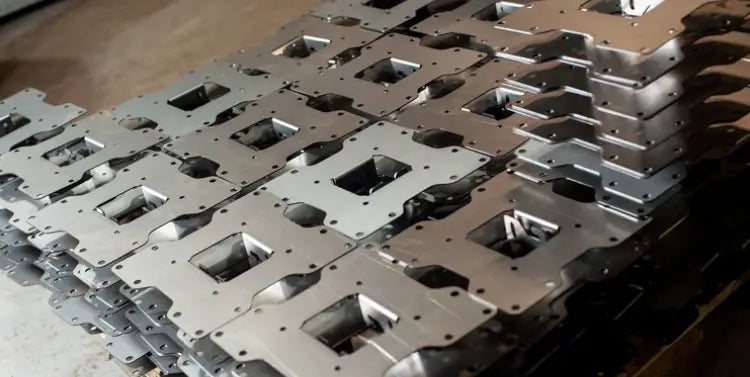

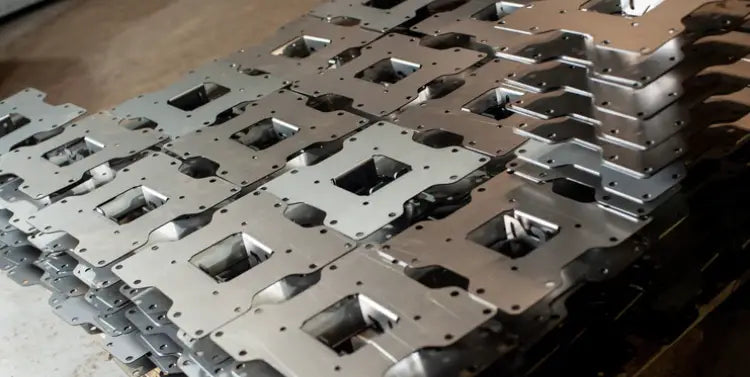

Precision and Versatility in Fabrication

The Amada EML-AJ at Fox delivers exceptional accuracy, working within tolerances of 0.07 mm. Four different size tapping stations enable efficient threading, while advanced forming capabilities can achieve embossments, extrusions, louvres and more with a laser cut finish all on one machine. The Amada machine can achieve up to 12,000 perforations per minute with Fox’s own tooling. The Combination laser punch machine offers customisable, high-quality solutions for intricate designs.

High-Speed Precision for Perforated Designs

Ourversatile machine combines laser cutting and punching to create perforated sheets with smooth laser-cut profiles, delivering precision and speed for intricate designs. It achieves up to 500 holes per minute using standard tooling or 12,000 perforations per minute with specialised Fox tooling, perfect for high volume production.

Durable and Precise Laser Etching

Laser etching provides durable, smooth-to-touch results, perfect for adding branding or instructions directly onto your products. Capable of creating complex designs and shades from mid-grey to black, it eliminates additional processing costs, ensuring high-quality finishes that meet your precise specifications and enhance your product's value.

Precision Punching for Plastic Sheet Projects

Our punch capabilities offers precise punching for plastic sheets, enabling intricate designs and consistent results. Ideal for your projects requiring accuracy, speed, and minimal waste, this process enhances efficiency and reduces costs, ensuring high-quality components tailored to your exact needs.

The Benefits of a Laser Punch Machine

Seamless Integration for Enhanced Efficiency

Seamless Integration for Enhanced Efficiency

Integrating the RMP 3015 PR automatic material management and part removal system with the

combination laser punch machine brings significant advantages. This system streamlines operations, enabling automated loading and unloading for improved throughput and enhanced productivity.

The key benefits include:

- Enhanced Efficiency: Automation reduces manual intervention, increasing throughput.

- Unmanned Operation: Supports continuous production without constant supervision.

- Space-Saving Design: Compact layout optimises floor space.

- Material Versatility: Handles various materials like mild steel, aluminium, stainless steel, galvanised, copper, brass, plastic.

Benefits You Will Gain

This integration translates to increased productivity, lower labour costs, and the flexibility to handle diverse production needs efficiently. You’ll benefit from streamlined operations, consistent quality, and reliable results tailored to meet your specific production goals.

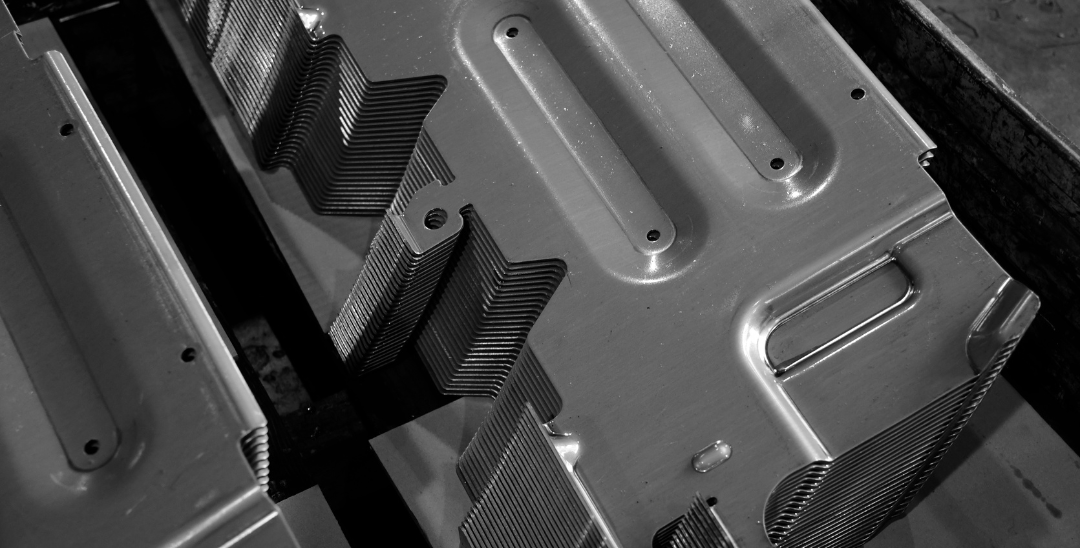

Enhanced Precision and Versatility

Enhanced Precision and Versatility

By integrating punching and fibre laser cutting, the EML-AJ can execute complex geometries and intricate designs with high accuracy, accommodating a wide range of materials and thicknesses.

Increased Productivity

Increased Productivity

The machine's dual servo electric punching system, delivering up to 30 tons of force, combined with a 3kW fibre laser, enables rapid processing speeds, reducing lead times and enhancing throughput.

Cost Efficiency

Cost Efficiency

Utilising fibre laser technology, the EML-AJ consumes up to 70% less electricity compared to traditional CO₂ systems, leading to lower operational costs. Additionally, its capability to perform multiple processes in a single setup minimises the need for secondary operations, further reducing labour and production expenses.

High-Quality Finishes

High-Quality Finishes

The machine's precise cutting and punching capabilities ensure clean edges and accurate dimensions, resulting in superior-quality components that meet stringent industry standards.

Flexibility in Production & Materials

Flexibility in Production & Materials

Equipped with a versatile turret featuring 44 stations, including tapping and forming, the EML-AJ allows for diverse fabrication tasks, enabling the creation of complex parts without additional machinery.

We can work in:

- Mild Steel

- Aluminium

- Stainless Steel

- Galvanised

- Copper

- Brass

- Plastic

Reduced Lead Times

Reduced Lead Times

By combining punching and laser cutting processes, the EML-AJ streamlines production workflows, leading to faster turnaround times and the ability to meet tight deadlines effectively.

Environmental Benefits

Environmental Benefits

The energy-efficient fibre laser technology not only lowers operational costs but also reduces the environmental footprint, aligning with sustainable manufacturing practices.

Your Trusted Partner for High-Quality Fabrication Solutions

Fox’s Amada EML-AJ ensures unmatched precision and flexibility for custom or high-volume projects. Contact us to discuss your needs or request a free consultation. Trust our expert team to deliver superior quality, meet tight deadlines, and provide cost-effective solutions tailored to you.