Subcontract Press Brake Solutions

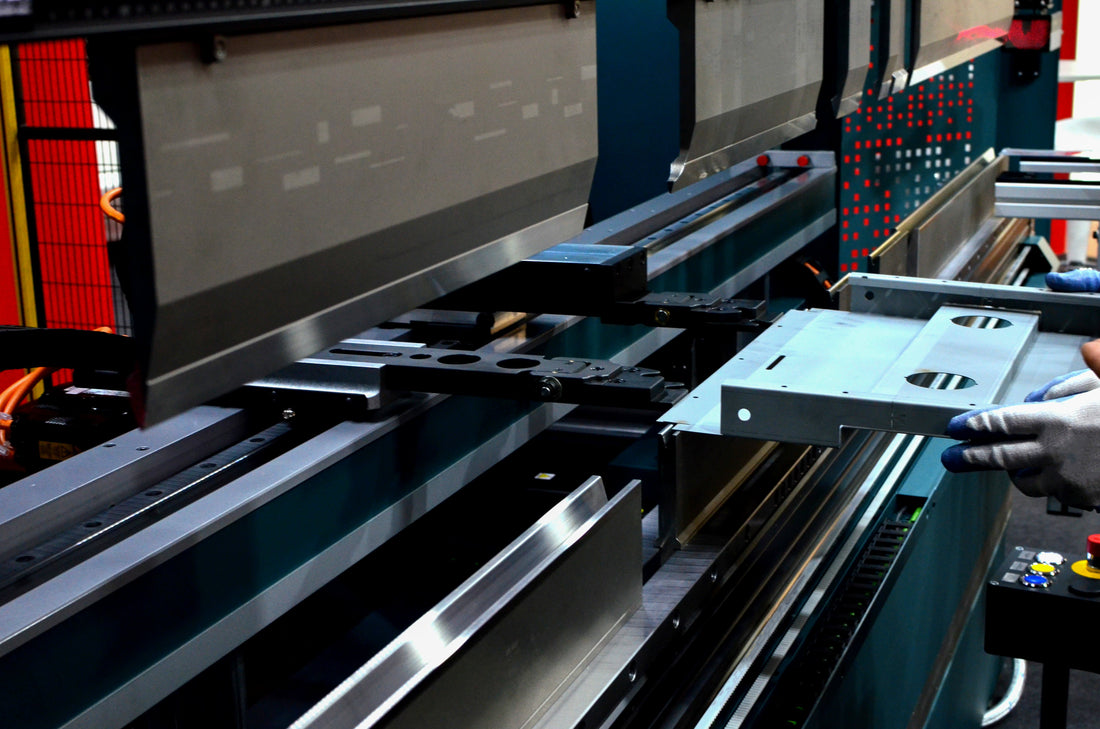

Press brake subcontracting is a critical service in the manufacturing industry, providing precision bending solutions for sheet metal components. At FDMS, our subcontract press brake services are tailored to meet the diverse needs of businesses across North Wales and beyond. Our focus on accuracy, consistency, and efficiency ensures that our clients receive high-quality parts that meet their exact specifications.

What is Press Brake Subcontracting?

Press brake subcontracting involves using advanced CNC-controlled press brakes to bend sheet metal into specific shapes and angles. These machines use a combination of force and precision tooling to create bends in various materials, including stainless steel, aluminium, mild steel, and other alloys. Subcontracting this process allows businesses to leverage the expertise and equipment of a specialised provider, without the need for significant capital investment.

Why Choose FDMS for Press Brake Subcontracting?

-

Advanced CNC-Controlled Press Brakes: Our state-of-the-art CNC press brakes ensure precise and repeatable bending results, reducing the risk of errors and maintaining consistent quality across large production runs.

-

Versatile Material Handling: We can bend a wide range of materials, from thin sheets to thicker plates, making our services suitable for various industries, including construction, automotive, electronics, and general manufacturing.

-

Customisable Bending Solutions: Our skilled operators can achieve complex bend profiles and radii, whether you need simple brackets or intricate enclosures.

-

Prototyping and Design Support: We provide consultation services to help optimise your designs for manufacturability, ensuring efficient production while maintaining design integrity.

Our Press Brake Capabilities

-

CNC Precision: Computer numerical control ensures exact bending angles and measurements.

-

Material Flexibility: Stainless steel, aluminium, mild steel, copper, and other materials can be processed.

-

Wide Range of Thicknesses: From thin sheets to thick plates.

-

Complex Bending Profiles: Achieve precise bends, angles, and radii as per your specifications.

Industries We Serve

Our press brake subcontracting services cater to a variety of sectors, including:

-

Construction: Fabrication of brackets, supports, and other structural components.

-

Automotive: Precision-formed panels, brackets, and support structures.

-

Electronics: Enclosures, chassis, and mounting brackets.

-

General Manufacturing: Custom components for machinery and equipment.

Quality Assurance

At FDMS, quality is at the heart of our press brake subcontracting services. Our skilled operators follow stringent quality control procedures, ensuring that every part meets your specifications. We use advanced measuring equipment to verify accuracy, and our CNC systems maintain consistency across all production runs.

Cost-Effective Solutions

By subcontracting your press brake requirements to FDMS, you eliminate the need for investing in expensive equipment and training. Our scalable services allow you to manage costs effectively, whether you need a small batch of components or a high-volume production run.

Serving North Wales and Beyond

Based in North Wales, FDMS proudly serves businesses across the region, providing reliable and responsive support. Our team works closely with clients to understand their requirements, ensuring that every project is delivered on time and within budget.

Contact Us

If you need reliable and cost-effective press brake subcontracting solutions, contact FDMS today. Our team is ready to discuss your project requirements, provide design advice, and deliver high-quality bent components that meet your exact specifications.

Frequently Asked Questions (FAQs) About Press Brake Subcontracting

1. What is press brake subcontracting, and why is it important?

Press brake subcontracting is a process where businesses outsource their metal bending requirements to a specialised provider equipped with advanced machinery. This process is essential because it allows companies to access high-quality, precision bending services without the need to invest in expensive equipment or skilled labour. By using subcontracting, businesses can maintain cost efficiency while ensuring consistent quality and precision in their metal components. It is particularly beneficial for companies that do not have the resources to purchase and maintain expensive press brake machines or hire skilled operators. With press brake subcontracting, you also benefit from the expertise of experienced operators who understand how to achieve precise bends, even for complex designs. This ensures that your components meet exact specifications without the risk of errors. As a result, press brake subcontracting is a valuable solution for manufacturers across industries, including automotive, construction, electronics, and general manufacturing.

2. How do I choose the right press brake subcontractor?

Choosing the right subcontractor involves several important considerations. First, assess their experience in the industry and their track record with clients in your sector. A reputable subcontractor should have advanced CNC-controlled press brake equipment capable of handling various materials and thicknesses. Check if they offer design support and prototyping services, which can help optimise your product for manufacturability. Evaluate their quality control procedures, ensuring they have a system for maintaining precision and consistency in every batch. It is also essential to confirm their capacity to handle your production volume, whether you need a small batch of components or a large production run. Look for customer reviews and testimonials that reflect their reliability and communication skills. Additionally, ensure that they provide transparent pricing without hidden costs. A good subcontractor should be willing to discuss your requirements, provide design advice, and offer a clear timeline for project delivery.

3. What materials can be processed using press brake subcontracting?

Press brake subcontracting is versatile and can accommodate a wide range of materials. Common options include stainless steel, which is known for its strength and corrosion resistance, making it suitable for industries like automotive and construction. Aluminium is another popular choice due to its lightweight nature and excellent conductivity, making it ideal for electronics and aerospace components. Mild steel is commonly used for general manufacturing applications, offering a good balance of strength and affordability. Copper and brass are also processed for specialised applications, such as electrical components and decorative finishes. Some subcontractors can also handle specialised alloys, providing greater flexibility for custom projects. The thickness of materials that can be processed depends on the subcontractor’s equipment capabilities. Generally, press brakes can handle thin sheets of less than 1mm to thicker plates exceeding 20mm. Always consult with your subcontractor to confirm they can handle the specific material type and thickness you require for your project.

4. How do press brake subcontractors ensure accuracy and quality?

Accuracy and quality are critical in press brake subcontracting, and reputable providers use a combination of advanced technology and skilled operators to achieve this. The use of CNC-controlled press brakes ensures precision, as computer numerical control allows for accurate bending angles and consistent results across large production runs. Skilled operators play a crucial role, monitoring the process and making necessary adjustments to maintain quality. Quality control procedures are also vital, with inspections carried out at various stages of production to verify measurements and ensure components meet specified tolerances. Advanced measuring tools, such as digital callipers and coordinate measuring machines (CMM), are often used to achieve this. Subcontractors may also offer design support, identifying potential issues in your designs and suggesting improvements for better manufacturability. This proactive approach helps prevent errors before production begins, ensuring that your components are produced accurately and to your specifications.

5. What are the cost advantages of press brake subcontracting?

The cost advantages of press brake subcontracting are significant, making it an ideal choice for businesses of all sizes. By outsourcing your metal bending needs, you avoid the high upfront cost of purchasing and maintaining expensive press brake machines. This also means you do not have to invest in training skilled operators or managing ongoing maintenance costs. Subcontracting provides cost flexibility, allowing you to pay only for the components you need, whether it is a small batch for prototyping or a large production run. Additionally, subcontractors benefit from economies of scale, which means they can offer competitive pricing due to their high production capacity. You also save on material wastage, as experienced subcontractors optimise the bending process to reduce scrap. Furthermore, working with a reliable subcontractor ensures that you receive high-quality components without the need for costly rework, further enhancing your cost savings.